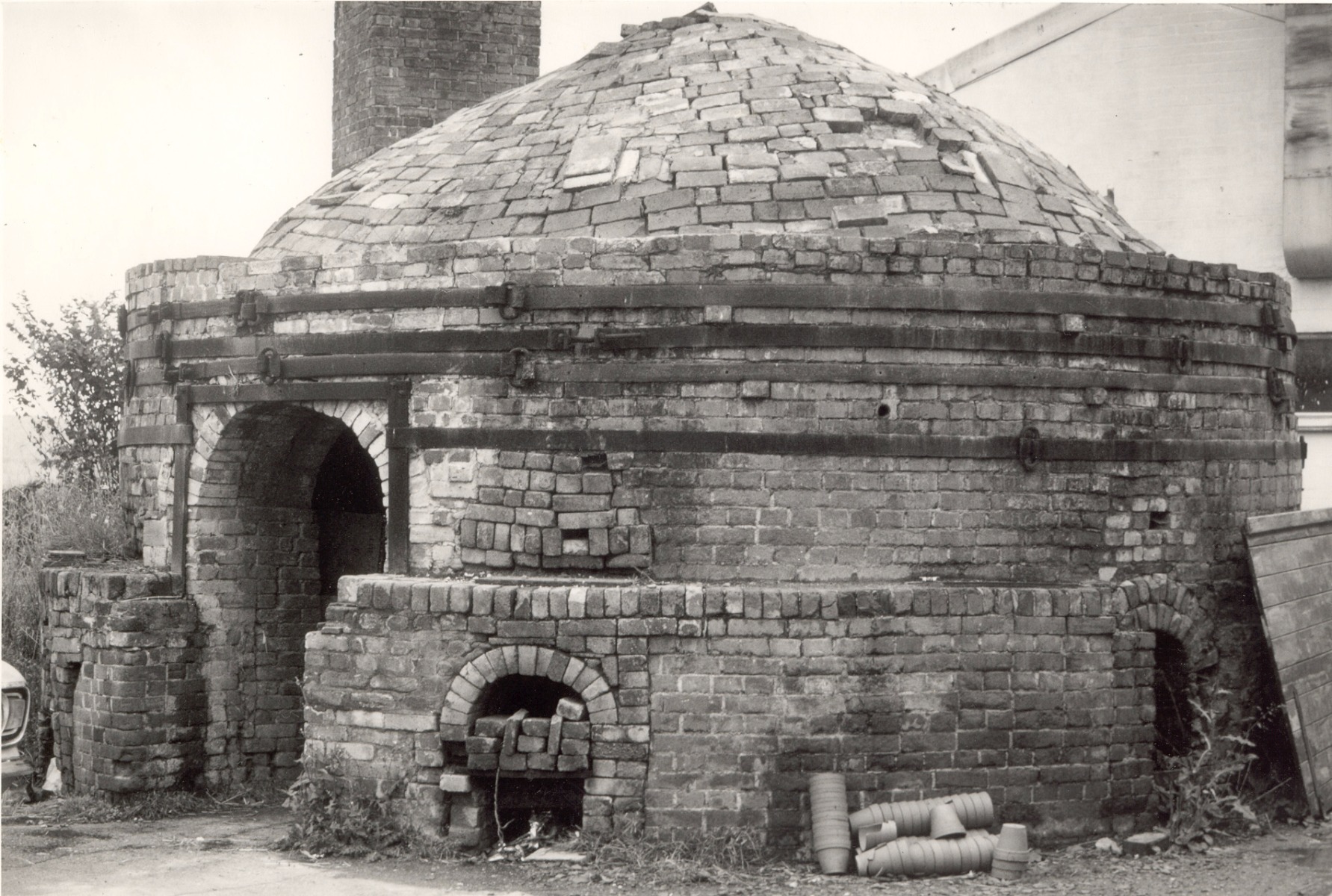

The Downdraft Kiln

This kiln was built in 1940/41 and was used up until 1963. A major fire destroyed the entire factory and a new factory was built installing electric kilns, the company then no longer required a kiln of this nature. The kiln was built in the evenings by staff who were then working in the factory. The dome was built using no support with just a few rounds of brick being laid every few days.

This kiln was built in 1940/41 and was used up until 1963. A major fire destroyed the entire factory and a new factory was built installing electric kilns, the company then no longer required a kiln of this nature. The kiln was built in the evenings by staff who were then working in the factory. The dome was built using no support with just a few rounds of brick being laid every few days.

The kiln was used initially as part of the war effort and fired land drain pipes throughout the Second World War. These pipes were subsequently purchased by the War Ministry and prisoners of war in the area dug these land drain pipes into the ground to improve the efficiency of crop yields. It was a coal-fired kiln and it burnt 5 tons of coal at each firing. This was either hauled from Elmswell railway station or brought from the coal mine by road.

Method of Operation

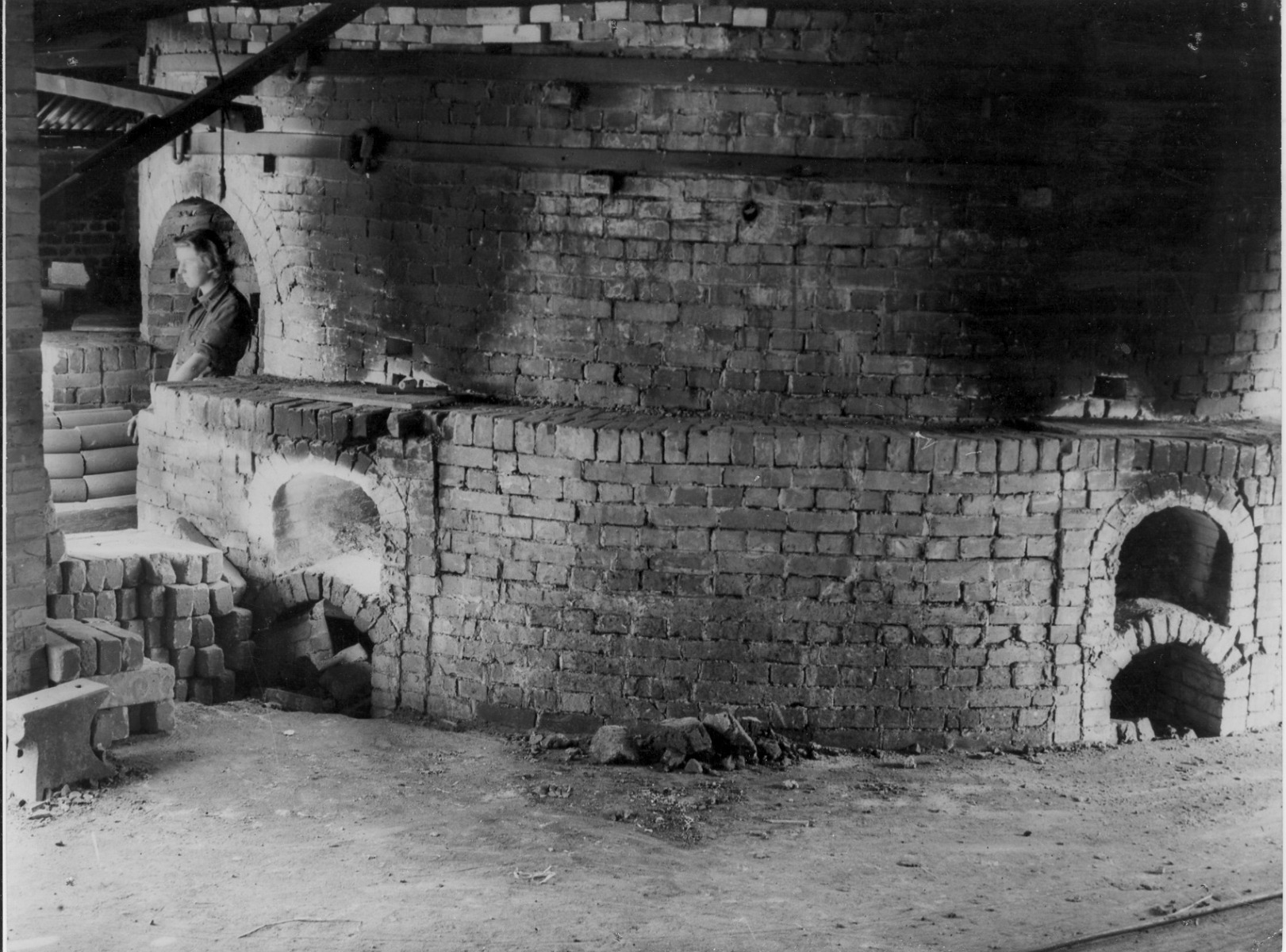

The kiln was designed as a down draft kiln which meant that the heat would not be released from the dome but would be drawn back down through the kiln load into the floor to the central flue which went underground and up the chimney stack. A large damper was used in the base of the chimney stack to control the draft.

The cycle of use for the kiln was weekly, as follows:

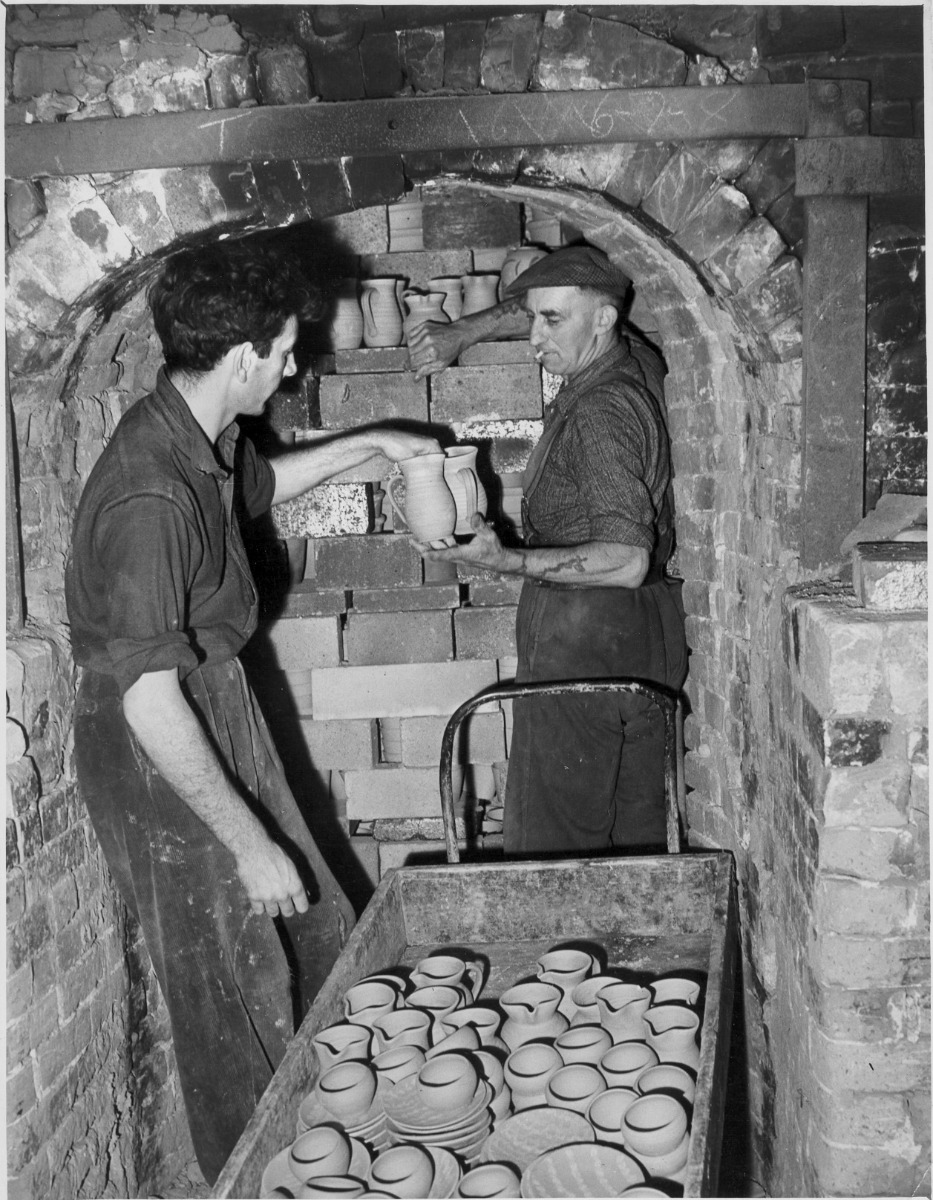

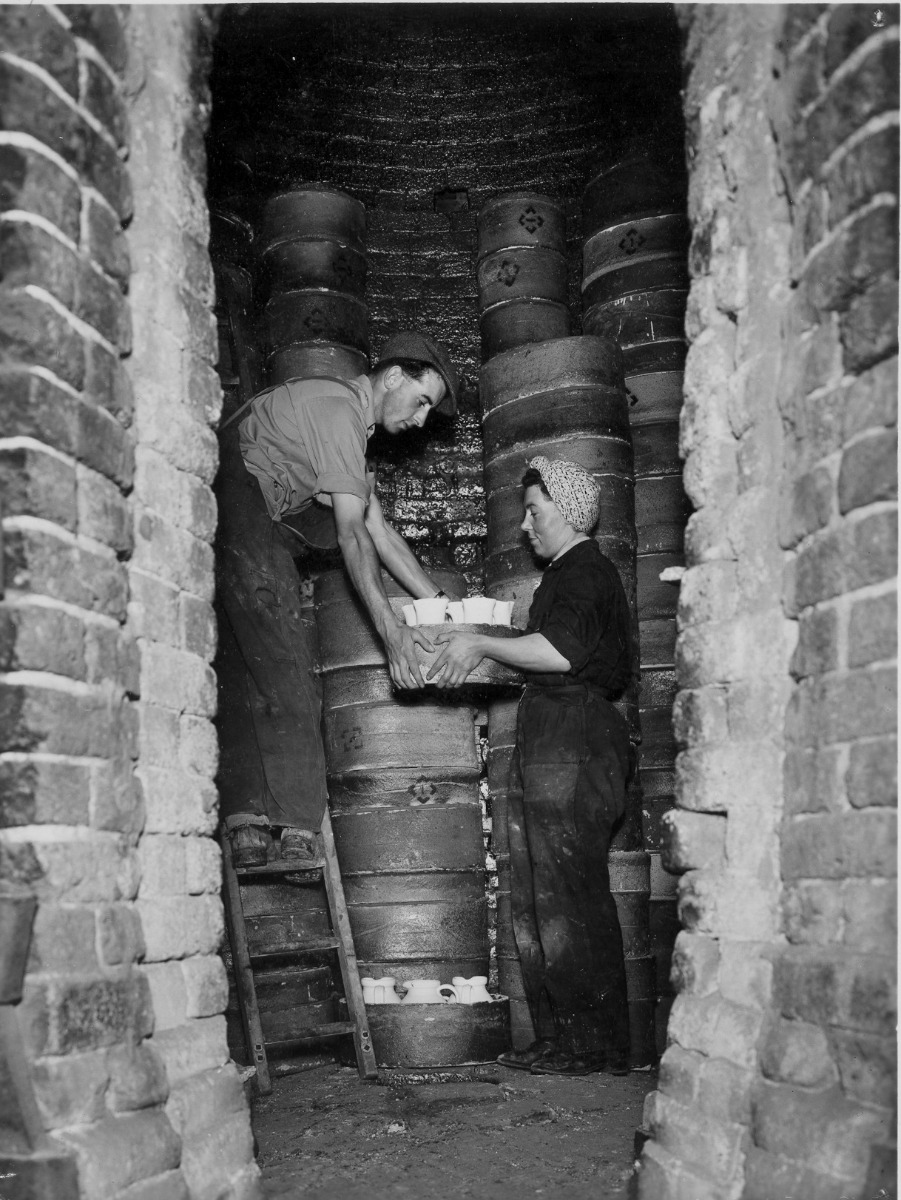

The kiln would be "drawn" (unloaded) on a Monday by a team of 6-8 people. This would take all day working in temperatures of 100oF plus. On Tuesday and Wednesday, the kiln would be packed. For most of its life horticultural flower pots were the main product being fired, with the kiln containing some 50,000 pieces. On Wednesday afternoon the doors were sealed with a covering of sand and clay plaster. On Wednesday evening small fires would be lit in each of the seven furnaces surrounding the kiln and these would be kept alight throughout the night and gradually increased in size. By Thursday lunch time the front of each furnace was bricked up and was fed from the top with a heavy plate being put into position to cover the opening. The furnaces were kept baited every hour for the next 24-30 hours until the final temperature was reached throughout the kiln. The sager cones which were visible through numerous spy holes were seen to curl over indicating that the appropriate temperatures had been reached - being anything up to 1000oC. Finalizing the kiln temperatures was an art in itself depending on wind directions and the type of coal being used with each furnace needing baiting adjustments to achieve the required even temperature. The kiln subsequently cooled throughout Friday night, Saturday and Sunday to the point where it could be entered on Monday morning once again to be drawn.